Defense Technology

Special solutions on land, on water and in the air

Defense Technology

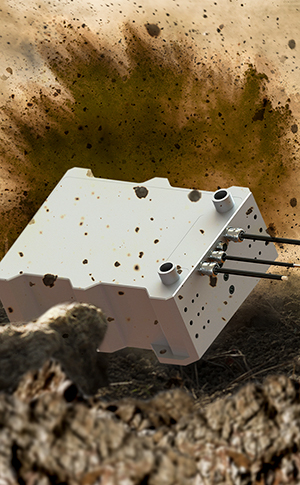

Security and defence technology places special demands on the components used. Special requirements in terms of operating conditions – whether at +40°C in the desert or -40°C in mountainous regions, in the thickest mud or the finest dust, at high altitudes or in salty air – must be taken into account when developing the components in order to ensure trouble-free and low-maintenance operation. Thanks to our decades of experience in railway technology, shipping and applications in the field of heavy vehicles and machines, such as mining trucks, excavators, wheel loaders and transporters, we are also able to develop suitable solutions for the special requirements of military technology. Not least thanks to our specially developed insulation and moisture protection system, the components are reliably protected against a wide range of environmental influences over the long term.

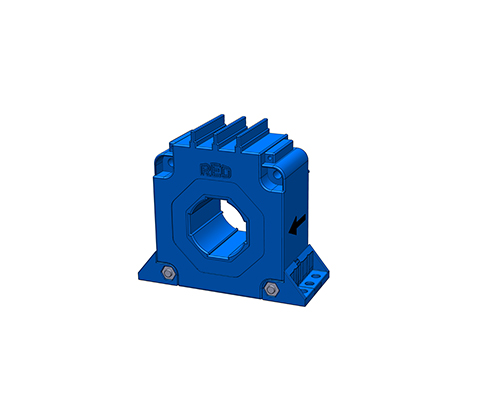

From EMC filters for reconnaissance and radar systems at sea, on land and in the air, braking resistors for military off-road vehicles or robots for explosive ordnance disposal, through to current transformers and EMC filters for use in tanks – REO develops and manufactures the optimum solution at its German production sites to meet the specific requirements of our partners.

We support the development and design of the desired components and carry out measurements, tests and simulations – also on site at our client’s premises.

Tests such as shock and vibration tests, salt spray tests, cold and heat tests, G-force tests or tests for water resistance or fire protection serve to ensure the resilience of the components.

Highlight of defense technology:

High protection classes for the highest demands

Products for defense technology

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.