Railway technology components

Railway technology components

Whether freight or passenger trains, high-speed trains, commuter trains or metros: REO components for railway technology ensure reliable and low-maintenance operation.

The requirements of railway technology are special: strong vibrations, large temperature fluctuations, dust, water and other adverse conditions place the highest demands on the components used. There are often limits to the air cooling of electrical components, for example, especially if the component has to be very compact. In order to continue to guarantee the best possible cooling, a wide range of inductive and resistive components from REO are equipped with Liquid cooling.

This not only enables optimum temperature behaviour of the component, but also promotes performance and ensures a longer service life of the components. Thanks to our many years of experience, the use of the highest quality materials and our innovative spirit, such as in the development of the REO insulation and moisture protection system, REO is a reliable partner in railway technology. The highest quality standards and extensive inspections and tests ensure trouble-free operation and a long service life with low maintenance requirements. This applies to both standard products and customised solutions developed with our customers.

Products for railroad technology

Highlight of rail technology

REO insulation system

MPS protective cover.

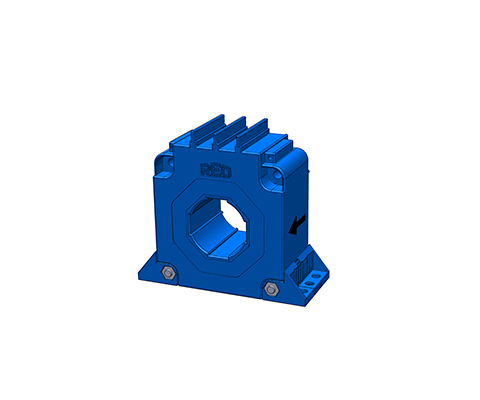

The MPS (Moisture Protection System) protective cover is a key component of the REO insulation system and a defining feature of REO’s products. Developed in-house and available exclusively from REO, the MPS protective cover ensures long-term reliability by shielding components from various environmental factors.

To provide effective outdoor protection against pantograph abrasion, brake dust, metal particles, snow, and ice, REO components receive this specialized protective coating in addition to VPI impregnation. This allows components to be exposed to unfiltered cooling air while maintaining an IP20 enclosure, offering significant flexibility in railway applications. For contamination levels exceeding PD3A,

REO relies on the MPS protective cover. REO offers its silicone coating options as REO Xtreme or REO Mix & Match.

Advantages of the REO Insulation System:

- Superior moisture protection

- High resistance to stone impacts

- Exceptional abrasion resistance (desert sand-proof)

- Suitable for degree of soiling> PD4a

- High tracking resistance (CTI > 600 V)

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.