Conserve resources

– act sustainably

Our path to CO2-neutral products and production

Sustainable production and products

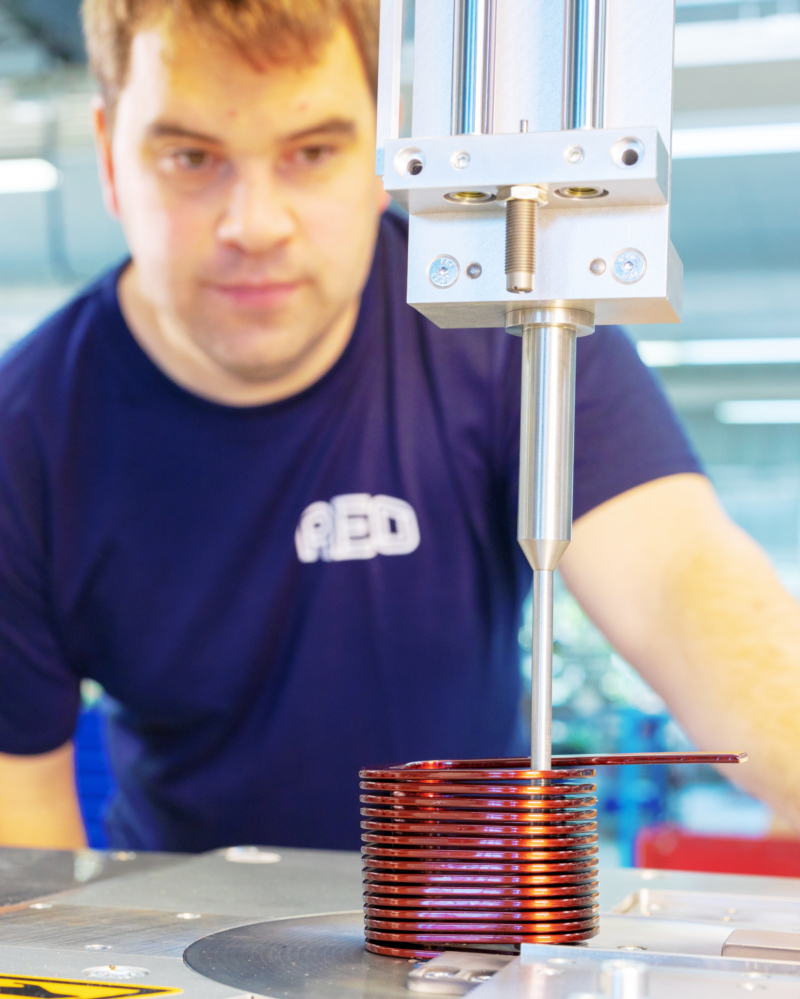

REO takes responsibility for our environment and sees itself as an active participant in the decarbonisation process. Therefore, we invest in CO2-neutral production at our sites and continuously develop our products. With the help of new technologies and new ways of thinking, we can constantly reduce energy consumption and emissions.

Innovations for CO2 neutrality

REO is on a consistent path to greater sustainability. We have set the course for a sustainable future and stand behind our ambitious goals. Our claim to be one of the leading suppliers of resistive and inductive components is based on a holistic strategy that includes all production and business areas. Learn more about our goals and our important milestones towards CO2-neutral production.

REO products conserve resources

With REO products, you can help minimise resource waste and ensure your devices and machines have a long service life and low maintenance requirements. As a result, you can invest in your facility or machinery with confidence, assuming a useful life of up to 30 years, and save financial resources by having comparatively very low maintenance costs.

Our path to zero emissions in production

As a global supplier of innovative resistive and inductive components, REO is committed to helping shape social transformation in the areas of industry, infrastructure, mobility, and lifestyle. We meet environmental protection requirements by constantly improving the environmental balance of our products and production.

To this end, we offer products for sustainable energy production and the electrification of industries previously powered by fossil fuels. In addition, our products contribute to a significant reduction in energy consumption and are manufactured in Germany in a resource-saving manner.

Through regular energy audits at our production sites and the implementation of an energy management system, we continuously identify optimisation and savings potential at our sites, especially in the areas of building envelopes, production processes, logistics, waste heat utilisation/heat recovery, electricity and heat supply, and lighting:

Potential CO2 reductions by location per year

Solingen

Kyritz

Berlin

Pfarrkirchen

Henningsdorff

First steps and successes

To implement these savings potentials, we have drawn up action plans for our sites: Measures that can be implemented quickly and pragmatically, such as introducing an intelligent heating control system, the use of rainwater or the conversion to LED technology, were implemented quickly. In addition, we have planned further investments for all locations, of which the first projects, such as the installation of a photovoltaic system and a heat pump heating system, the use of resource-saving and energy-saving machines or the replacement of windows on the buildings, have already been successfully implemented.

All these efforts are already having a positive effect on our environmental balance. For example, in 2024, we achieved a 23% reduction in CO2 equivalents compared to 2021.

We are proud of the progress made so far and continue our path to CO2 neutrality with full energy!

Decarbonization

- Reduction of energy demand

- Preparation for CO2-neutral production

- Green electricity from own PV systems

- Reduction of electricity consumption

- Installation of LED lights

- Expansion of charging infrastructure for e-mobility

- Modern peak load management

- Smart heating control

Resource efficiency

- Optimization of products and material usage

- Reduction of copper waste

- Reduction of fuel consumption

- Optimization of process flows

- Use of reusable packaging

- Reusable water bottles for employees

- All products comply with RoHS / REACH

- Recycling of secondary raw materials (copper, aluminum, metals)

Water usage

- Recording of water consumption

- Reduction of water consumption

- Use of rainwater

- Transition to ecologically degradable cleaning agents

Your advantage: Save money and protect the environment at the same time

By using the highest quality materials and energy-efficient machines, as well as careful processing, we save resources in production and extend the lifespan of our products. Compared to inferior products with high maintenance requirements and short lifespans, using REO components not only saves you costs over the entire operating period, but also protects the environment through reduced resource use, as the consumption of materials for replacement and new production is significantly reduced.