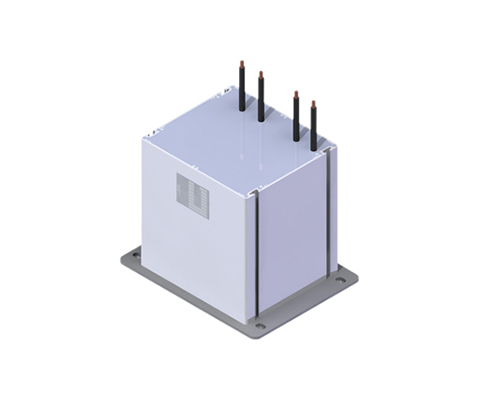

Buck converter chokes NTT UI114-50

REO TSS reactor with iron core Description The buck converter reactor as an inductive passive component in the power supply and in power electronics is used to attenuate unwanted frequencies or for saving energy and storage. The term buck-converter reactor indicates the complete ready-for-use unit containing the choke, air cooling, mounting and connections. The reactors are available with different cores, which enables individual selection depending on the requirement of the application. In addition to iron-based cores, reactors with cores of amorphous alloy are becoming more common, in the form of toroidal cores, cut strip-wound cores or special custom solutions. The use of amorphous materials offers an exceptional combination of high saturation flux density (1.56 T) and a high permeability. In addition to the high temperature class, further features of amorphous alloy include low hysteresis and eddy-current losses, suitability for the medium-frequency range (<20 kHz) and use for high powers up to 500 kVA. Advantages Lower losses in comparison with grain-oriented sheet Can be used in the kHz region Equal or higher power ranges with smaller components Significantly lower weight High flux densities Usable up to temperature class H (180°C) Protection class IP 65 Technical Data Type of reactor: Up/Buck converter reactor with iron core Voltage of the system: 500 – 1100 V Max. permissible tolerances: ( -10 % / +10 % ) Linearity: min. 0.2 mH @ 230 Aeff Harmonic currents constantly / Superimposed Harmonics: 60 Ass @ 19 kHz Insulation class: H Cooling: AF Protection rating: IP65/66 Rated voltage for insulation: 1200 Vdc Test voltage: 3.5 kV (50 Hz, 60 s) Technical specification Voltage [V] 500 – 1100 Rated current [A] 120 Linearity @230 A [mH] min. 0.2 @ 230 Aeff Nominal inductance[mH] 0,2 Resistance [mΩ] 3,7 @ 20°C/ 5,1 @ 120°C Losses [W] ≤ 170 W @ 120°C Cooper [kg] 4,4 Weight [kg] 17,4

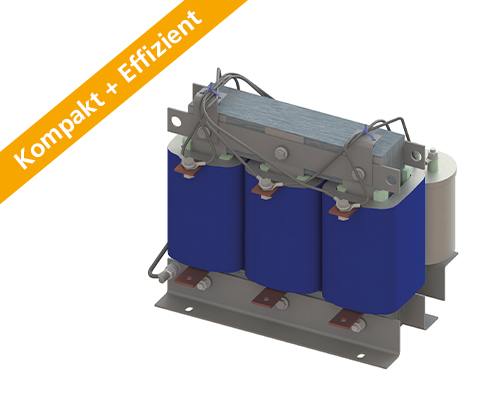

Buck converter chokes NTT AMCC 400

REO TSS reactor with amorphous core Description The buck converter reactor as an inductive passive component in the power supply and in power electronics is used to attenuate unwanted frequencies or for saving energy and storage. The term buck-converter reactor indicates the complete ready-for-use unit containing the choke, air cooling, mounting and connections. The reactors are available with different cores, which enables individual selection depending on the requirement of the application. In addition to iron-based cores, reactors with cores of amorphous alloy are becoming more common, in the form of toroidal cores, cut strip-wound cores or special custom solutions. The use of amorphous materials offers a special combination of high saturation induction (1.56 T) and high permeability. Low remagnetization losses as well as the possibility of use in the medium frequency range (< 20 kHz) and at high powers of up to 500 kVA are additional features of amorphous alloys, alongside their high thermal class. Advantages Lower losses in comparison with grain-oriented sheet Can be used in the kHz region Equal or higher power ranges with smaller components Significantly lower weight High flux densities Usable up to temperature class H (180°C) Protection class IP 65 Technical Data Type of reactor: Up/Buck converter reactor with iron core Voltage of the system: 500 – 1100 V Max. permissible tolerances: ( -10 % / +10 % ) Linearity: min. 0.2 mH @ 230 Aeff Harmonic currents constantly / Superimposed Harmonics: 60 Ass @ 19 kHz Insulation class: H Cooling: AF Protection rating: IP65/66 Rated voltage for insulation: 1200 Vdc Test voltage: 3.5 kV (50 Hz, 60 s) Technical specification Voltage [V] 500 – 1100 Rated current [A] 120 Linearity @230 A [mH] min. 0.2 @ 230 Aeff Nominal inductance[mH] 0,2 Resistance [mΩ] 4,19 @ 20°C 5,83 @ 170°C Losses [W] ≤ 155 W @ 107°C Cooper [kg] 2,2 Weight [kg] 9,8 Data sheet Download our extensive catalog and discover many other REO products. Download Data sheet Certifications

Sine wave filter CNW 961

Discover the CNW 961 sine filter for reliable performance in water treatment and heat pump systems.

Sine wave filter N CNW 933

The new series not only scores points for its faster delivery time, but also for its resource conservation and increased efficiency.

Motor Choke N CNW 854

Three-phase motor choke Description Compact & Efficient The new series not only scores points for its faster delivery time, but also for its resource conservation and increased efficiency. Reduce voltage rise (< 200V / µs) and distortions – optimally protect electrical consumers. In addition to voltage rises, there is a considerable amount of symmetrical and asymmetrical current distortions generated at the motor supply line due to the rapid switching of power semiconductors. These become more pronounced with increasing cable length. These disturbances can affect the motor’s performance through loud noises and, in extreme cases, through overheating. A motor choke can provide a remedy here. The motor choke reduces the voltage rise and voltage peaks between the conductors. Furthermore, the current is smoothed. Losses and heating are minimized and leakage current is reduced. Longer motor cable lengths can be used. The motor insulation is protected, thus increasing its lifespan. The motor choke also dampens conducted interference in the lower frequency range very well. Losses and typical noises in the motor laminations are reduced. Voltage rises are reduced to (< 200V / µs.) Increasing the service life of motors, lowering the edge steepness du / dt to earth and between the phases, reducing motor noise, and current smoothing. Advantages Protection for electrical consumers Limitation of voltage rise to < 200V/µs Extended service life of electrical consumers Reduction of engine noise Low leakage currents on the motor Longer motor cables are possible Easy construction Compact design Production possible according to UL insulation system E251513 TYPICAL APPLICATIONS Drive systems for motor drives, Mechanical engineering, Elevators / escalators, Pipes, Conveyor technology, Ventilation and air conditioning, Robotics, Automation technology, Power supplies, Wind turbines Technical Data Reduction of voltage rise du/dt to < 200V/µs Field frequency: 0 – 60 Hz Drive Switching frequency of the inverter: up to 150 A >4kHz, from 150 A >1.5kHz According to: EN 60289 / EN 61558 Test voltage: L-L 2500 V, AC/50Hz 60s; L-PE 2500 V, AC/50Hz 60s Insulation class: T40/F Protection rating: IP00 Climatic category: DIN IEC 60068-1 Overload: 1,5 x INenn 1 min / h Ambient temperature: 40 °C Design: standing on foot angle Technical specification Type Nominal voltage U [V] Nominal current I [A] Inductance L [mH] Losses P [W] Mass [kg] Mass Cu [kg] Mass Al [kg] N CNW 854 / 2 500 50 / 60 Hz 2 7,00 21 1,0 0,3 – N CNW 854 / 4 4 3,60 26 1,1 0,5 – N CNW 854 / 8 8 2,00 35 2,0 0,5 – N CNW 854 / 10 10 1,70 44 2,2 0,9 – N CNW 854 / 12 12 1,20 52 2,7 0,8 – N CNW 854 / 16 16 0,90 54 2,8 0,9 – N CNW 854 / 24 24 0,70 55 4,4 1,9 – N CNW 854 / 30 30 0,50 40 4,5 0,9 – N CNW 854 / 37 37 0,42 40 6,0 1,4 – N CNW 854 / 48 48 0,32 60 7,0 1,9 – N CNW 854 / 60 60 0,28 80 7,0 2,0 – N CNW 854 / 75 75 0,22 100 8,0 1,4 – N CNW 854 / 90 90 0,17 80 10,0 1,9 – N CNW 854 / 115 115 0,14 150 14,0 1,6 – N CNW 854 / 150 150 0,11 170 16,0 3,1 – N CNW 854 / 180 180 0,09 160 18,0 3,2 – N CNW 854 / 200 200 0,08 170 23,0 2,8 – N CNW 854 / 250 250 0,065 240 24,0 3,8 – N CNW 854 / 300 300 0,053 380 44,0 1,5 2,7 N CNW 854 / 350 350 0,046 330 55,0 2,6 4,6 N CNW 854 / 400 400 0,041 380 58,0 2,6 4,9 N CNW 854 / 500 500 0,032 520 63,0 2,6 5,2 N CNW 854 / 600 600 0,028 650 65,0 5,0 5,9 N CNW 854 / 700 700 0,024 820 86,0 5,0 5,7 N CNW 854 / 800 800 0,021 710 108,0 6,6 9,0 N CNW 854 / 900 900 0,018 800 114,0 13,8 7,6 N CNW 854 / 1000 1000 0,016 900 114,0 13,8 7,6 N CNW 854 / 1200 1200 0,013 1170 122,0 13,8 8,0 DIMENSIONS IN MM Type Length L1 [mm] Length L2 [mm] Width B1 [mm] Width B2 [mm] High max. H1 [mm] Fastening N1 [mm] Fastening N2 [mm] Fastening D1 [mm x mm] Clamp/ cable lug [mm²] Angle [mm x mm] Port A1 [mm] Port D2 [mm] PE Ø [mm] N CNW 854 / 2 80 96 45 55 110 56 34 5 x 8 2.5 – – – M4 N CNW 854 / 4 80 96 45 55 110 56 34 5 x 8 2.5 – – – M4 N CNW 854 / 8 80 96 55 65 110 56 43 5 x 8 2.5 – – – M4 N CNW 854 / 10 125 120 61 66 130 100 45 5 x 8 2.5 – – – M4 N CNW 854 / 12 125 120 71 67 130 100 55 5 x 8 2.5 – – – M4 N CNW 854 / 16 125 120 71 67 130 100 55 5 x 8 2.5 – – – M4 N CNW 854 / 24 155 150 76 86 170 130 54 8 x 12 10 – – – M4 N CNW 854 / 30 155 – 110 130 130 54 8 x 12 16 (M6) – 40 – M6 N CNW 854 / 37 155 – 125 130 130 69 8 x 12 16 (M6) – 40 – M6 N CNW 854 / 48 190 – 115 165 170 57 57 8 x 12 16 (M8) – 40 – M8 N CNW 854 / 60 190 – 115 165 170 57 57 8 x 12 16 (M8) – 40 – M8 N CNW 854 / 75 190 – 135 160 170 67 67 8 x 12 16 (M8) – 40 – M8 N CNW 854 / 90 190 – 135 160 170 77 77 8 x 12

Harmonic Filter CNW 897

Three-phase harmonic filter (400 V / 50/60 Hz) DESCRIPTION The filter is designed for the reduction of the THD (Total Harmonic Distortion) when used with B12 rectifiers. The harmonic currents are extremely suppressed so that the THD is reduced to lower than 5 % (for example in UPS-systems).Typical values of Total Harmonic Distortion with B12 rectifiers and the use of transformers are between 12 and 13%. This complies with the EN 61000-3-4 and EN 61000-3-12 standards.If more severe conditions for the mains are defined, in addition to the transformer it is necessary to use REO-Harmonic-Filter type CNW 897. These filters are available in two different versions: THD < <5% THD < <10 % The IP00 version is especially suitable for panel mounting and can be mounted to save space here. The CNW 897 helps to comply with international power quality standards IEEE 519 or EN 61000-3. Advantages Reduction of the THDI value Low voltage drop Increasing network stability Reduction of the input current up to 30% Suitable for installation in control cabinets easy integration into existing systems Increased reliability of electrical installations Technical specification According to: EN 60289 / EN 61558 Test voltage: L-L 2500 V, DC 1min; L-PE 2500 V, DC 1min Insulation class: T40/F Climatic category: DIN IEC 60068-1 Protection: IP 00 (also available as IP20 version) Nominal voltage: 400V / 50 Hz Standards: IEEE 519, EN 61000-3-12, EN 61000-3-2, IEC 61000-3-4 Type Rated voltage /Rated frequency [V] Rated current 3x [A] Inductance 3x [mH] Capacity capacitor [μF] Rated power [kVA] Power dissipation [W] Cu /AI [kg] Weight throttle [kg] Weight Condi [kg] CNW 897/25/400/5% 3×400 50/60 Hz 25 2,9 3 x 68 17,3 70 9/ 0 20 5,98 CNW 897/40/400/5% 3×400 50/60 Hz 40 2,48 3 x 80 27,7 90 11/ 0 26 6,58 CNW 897/70/400/5% 3×400 50/60 Hz 70 1,1 3 x 180 48,5 130 18/ 0 32 10,18 CNW 897/90/400/5% 3×400 50/60 Hz 90 0,9 3 x 220 62,4 200 0.8/ 3.4 49 12,58 CNW 897/120/400/5% 3×400 50/60 Hz 120 0,75 3 x 220 + 3 x 40 83,1 250 0.8/5.1 59 17,66 CNW 897/150/400/5% 3×400 50/60 Hz 150 0,6 3 x 330 103,9 350 1/ 8.4 59 16,78 CNW 897/180/400/5% 3×400 50/60 Hz 180 0,5 3 x 330 + 3 x 180 124,7 330 1.1/ 8.4 65 21,86 CNW 897/250/400/5% 3×400 50/60 Hz 250 0,36 3 x 330 + 3 x 220 173,2 440 1.7/ 12.8 82 29,33 CNW 897/310/400/5% 3×400 50/60 Hz 310 0,3 6 x 330 214,8 570 1.9 /14 95 33,53 CNW 897/400/400/5% 3×400 50/60 Hz 400 0,225 6 x 330 +3 x 220 277,1 910 3 / 10.1 108 45,2 CNW 897/600/400/5% 3×400 50/60 Hz 600 0,2 9 x 330 415,7 1040 6.4 / 22.8 193 49,4

du/dt Choke N CNW 806

Three-phase dv/dt filter DESCRIPTION NEW SERIES! The new series not only scores points for its faster delivery time, but also for its resource conservation and increased efficiency. Reduce voltage rise to < 500V / µs – protect electrical loads and insulation cost-effectively. A simple and cost-effective method to reduce the voltage rise rate is to use a du/dt choke or filter. It dampens the voltage rise to tolerable values and prevents overvoltages on long supply lines. Losses and heating are minimized, and the leakage current is reduced. By limiting the voltage steepness, the motor insulation is protected, thus extending its service life. EMC interference in the radiation range from 1 MHz to 30 MHz is also reduced. ADVANTAGES Protection for electrical consumers Limitation of voltage rise to < 500V / µs Extended service life of electrical consumers Low leakage currents on the motor Reduced losses Easy construction Compact design Production possible according to UL insulation system E251513 TYPICAL APPLICATIONS Drive systems for motor drives, Mechanical engineering, Elevators / escalators, Pipes, Conveyor technology, Ventilation and air conditioning, Robotics, Automation technology, Power supplies, Wind turbines Technical Data Rated voltage: U ≤ 3 x 500 V Reduction of voltage rise du/dt to < 500V/µs Field frequency: 0 – 60 Hz Drive Switching frequency of the inverter: up to 150 A >4kHz, from 150 A >1.5kHz According to: EN 60289 / EN 61558 Test voltage: L-L 2500 V, AC/50Hz 60s; L-PE 2500 V, AC/50Hz 60s Insulation class: T40/F Protection rating: IP00 Climatic category: DIN IEC 60068-1 Overload: 1,5 x INenn 1 min / h Ambient temperature: 40 °C Design: standing on foot angle TECHNICAL SPECIFICATION Type Nominal voltage U [V] Nominal current I [A] Inductance L [mH] Resistance R [mΩ] Losses P [W] UK at 400 V, 50 Hz [%] UK at 230 V, 50 Hz [%] UK at 480 V, 60 Hz [%] UK at 500 V, 50 Hz [%] Mass[kg] [kg] Weight Cu [kg] Weight Al [kg] N CNW 806 / 4 500 50 / 60 Hz 4 1,500 92,7 10 0,8 1,4 0,8 0,7 1,0 0,12 N CNW 806 / 10 500 50 / 60 Hz 10 0,600 26,4 20 0,8 1,4 0,8 0,7 2,0 0,15 N CNW 806 / 18 500 50 / 60 Hz 18 0,330 12,0 20 0,8 1,4 0,8 0,6 2,0 0,21 N CNW 806 / 24 500 50 / 60 Hz 24 0,245 9,1 30 0,8 1,4 0,8 0,6 2,5 0,24 N CNW 806 / 37 500 50 / 60 Hz 37 0,160 4,8 30 0,8 1,4 0,8 0,6 3,0 0,57 N CNW 806 / 48 500 50 / 60 Hz 48 0,123 2,7 40 0,8 1,4 0,8 0,6 3,0 0,45 N CNW 806 / 65 500 50 / 60 Hz 65 0,090 2,0 50 0,8 1,4 0,8 0,6 4,0 0,57 N CNW 806 / 90 500 50 / 60 Hz 90 0,065 1,5 60 0,8 1,4 0,8 0,6 5,0 0,72 N CNW 806 / 120 500 50 / 60 Hz 120 0,050 1,1 80 0,8 1,4 0,8 0,7 7,0 1,44 N CNW 806 / 150 500 50 / 60 Hz 150 0,039 0,5 60 0,8 1,4 0,8 0,6 8,0 1,65 N CNW 806 / 180 500 50 / 60 Hz 180 0,033 0,5 80 0,8 1,4 0,8 0,6 9,0 1,35 N CNW 806 / 200 500 50 / 60 Hz 200 0,029 0,5 100 0,8 1,4 0,8 0,6 9,0 1,50 N CNW 806 / 250 500 50 / 60 Hz 250 0,024 0,22 120 0,8 1,4 0,8 0,7 15,0 1,10 1,50 N CNW 806 / 300 500 50 / 60 Hz 300 0,020 0,15 140 0,8 1,4 0,8 0,7 16,0 1,10 2,55 N CNW 806 / 350 500 50 / 60 Hz 350 0,017 0,13 140 0,8 1,4 0,8 0,6 21,0 6,5 N CNW 806 / 400 500 50 / 60 Hz 400 0,015 0,10 150 0,8 1,4 0,8 0,7 24,0 2,2 2,25 N CNW 806 / 500 500 50 / 60 Hz 500 0,012 0,10 200 0,8 1,4 0,8 0,7 27,0 2,60 3,30 N CNW 806 / 600 500 50 / 60 Hz 600 0,010 0,08 250 0,8 1,4 0,8 0,7 32,0 4,40 2,55 N CNW 806 / 700 500 50 / 60 Hz 700 0,008 0,07 260 0,8 1,3 0,8 0,6 35,0 4,90 3,00 N CNW 806 / 800 500 50 / 60 Hz 800 0,007 0,06 280 0,8 1,3 0,8 0,6 36,0 5,20 3,90 N CNW 806 /900 500 50 / 60 Hz 900 0,0065 0,05 290 0,8 1,4 0,8 0,6 55,0 10,8 5,55 N CNW 806 / 1000 500 50 / 60 Hz 1000 0,006 0,05 360 0,8 1,4 0,8 0,7 56,0 10,8 5,85 N CNW 806 / 1200 500 50 / 60 Hz 1200 0,005 0,05 480 0,8 1,4 0,8 0,7 56,0 10,8 6,00 DIMENSIONS IN MM Type Length Width High max. Mounting Clamps/Cross section [mm²] Connection L1 [mm] L2 [mm] B1 [mm] B2 [mm] H1 [mm] N1 [mm] N2 [mm] D1 [mm x mm] Angle [mm x mm] A1 [mm] D2 [mm] PE Ø [mm] N CNW 806 / 4 65 78 50 60 95 50 38 5 x 8 2,5 – – – M4 N CNW 806 / 10 80 96 45 55 110 65 34 5 x 8 2,5 – – – M4 N CNW 806 / 18 80 96 5 65 110 65 43 5 x 8 2,5 – – – M4 N CNW 806 / 24 125 120 61 76 145 100 45 5 x 8 10 – – – M4 N CNW 806 / 37 125 – 90 – 105 100 45 5 x 8 10 (M6) – 40 – M6 N CNW 806 / 48 125 – 100 – 105 100 55 5 x 8 10 (M6) – 40 – M6 N CNW 806 / 65 155 – 110 – 130 130 54 8 x 12 16 (M8) – 40 – M6 N CNW 806 / 90 155 – 120 – 130 130 69 8 x 12 16 (M8) – 40 –

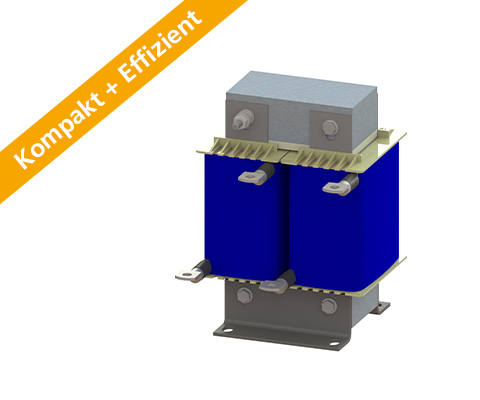

DC-Link Choke N CNW 892

DC-link chokes (2 lines) Description Compact & efficient Reduce grid disturbances – save energy costs. The DC-link reactor is used for smoothing the DC link current and to reduce mains harmonics in voltage source inverters. The typical combinations of rectifiers and capacitors strains the supply network significantly. For functional reasons, the current consumption of the power supply or the inverter is not sinusoidal but pulsed at the moment of maximum voltage. DC-link reactor reduce the harmonics and relieve the supply network similar to the mains choke. In addition, the DC-link reactor attenuates charging current peak surges of the DC-link capacitors. By using a DC-link reactor the supply network is less burdened with harmonic reactive power. Improvement of the efficiency of a converter (Power Factor Correction). Starting currents and current peak are attenuated up to 70%. Line reactors help to comply with international power quality standards IEEE 519 or EN 61000-3-2. Advantages Reduction of harmonics waves Attenuation of current spikes of up to 70% Compact design Advantages over line reactor: Smaller size Lower cost of materials / Price Smaller power loss Production possible according to UL insulation system E251513 TYPICAL APPLICATIONS Drive systems for motor drives, Mechanical engineering, Elevators / escalators, Pipes, Conveyor technology, Ventilation and air conditioning, Robotics, Automation technology, Power supplies, Wind turbines Technical Data Rated voltage: U ≤ 800 V According to: EN 60289 / EN 61558 Test voltage: L-PE 4000 V, AC/50Hz, 60s Insulation class: T40/F Protection rating: IP00 Climatic category: DIN IEC 60068-1 Overload: 1,5 x INenn 1 min / h Design: standing on foot angle Technical specification Type Nominal voltage U [V] Nominal current I [A] Inductance L [mH] Losses P [W] Mass [kg] Mass Cu [kg] N CNW 892 / 8 600 50 / 60 Hz 8 9,4 30 1,4 0,6 N CNW 892 / 11 600 50 / 60 Hz 11 6,2 30 2,0 0,6 N CNW 892 / 15 600 50 / 60 Hz 15 4,8 40 2,4 0,8 N CNW 892 / 20 800 50 / 60 Hz 20 3,3 30 3,0 1,2 N CNW 892 / 28 800 50 / 60 Hz 28 2,4 40 3,8 2,1 N CNW 892 / 34 800 50 / 60 Hz 34 2,0 40 4,0 1,3 N CNW 892 / 40 800 50 / 60 Hz 40 1,6 70 5,0 1,2 N CNW 892 / 55 800 50 / 60 Hz 55 1,2 80 6,0 1,4 N CNW 892 / 70 800 50 / 60 Hz 70 0,98 80 8,0 2,3 N CNW 892 / 85 800 50 / 60 Hz 85 0,81 90 11,0 2,0 N CNW 892 / 100 800 50 / 60 Hz 100 0,67 120 13,0 1,8 DIMENSIONS IN MM Type Dimensions L (mm) Dimensions B (mm) Dimensions H (mm) Mounting N1 (mm) Attachment N2 (mm) Mounting D1 (mm) Terminal connection/Cable lug[mm²] Connection PE Connection A1 (mm) Design N CNW 892 / 8 80 53 135 50 39 4,8 x 9 4,0 M4 1 N CNW 892 / 11 80 63 135 50 49 4,8 x 9 4,0 M4 1 N CNW 892 / 15 100 66 155 63 49 6 x 10 4,0 M4 1 N CNW 892 / 20 100 66 140 63 49 6 x 10 10 (M4) M4 35 2 N CNW 892 / 28 100 81 140 63 64 6 x 10 10 (M5) M4 35 2 N CNW 892 / 34 100 81 140 63 64 6 x 10 16 (M5) M4 35 2 N CNW 892 / 40 120 87,5 165 76 68,5 7 x 13 10 (M6) M6 40 3 N CNW 892 / 55 120 97,5 165 76 78,5 7 x 13 16 (M6) M6 40 3 N CNW 892 / 70 152 92 205 100 73 7 x 13 25 (M8) M8 45 3 N CNW 892 / 85 152 112 205 100 93 7 x 13 25 (M8) M8 45 3 N CNW 892 / 100 160 127 215 100 103 7 x 13 25 (M8) M8 45 3 Data sheet Download our extensive catalog and discover many other REO products. Download Data sheet Certifications

Liquid-cooled choke MD 953

Liquid-cooled three-phase mains choke 8% Uk Description Water cooled chokes are available with ingress protection ratings IP00 to IP65. REO can utilize several methods of water cooling these components. This provides controlled conduction of heat losses, ensuring that the local environment is not heated. Water cooling ensures that component temperatures are greatly reduced, reducing component stress and increasing product life. REO technology provides excellent heat distribution, preventing the emergence of so-called hot spots. Advantages Protection class up to IP 65 Longer lifetime Optimal heat dissipation Suitable for railway applications Technical Data Insulation class: F Cooling medium: water/glycol (other cooling liquids on request) Max. Coolant inlet temperature: 50° C Rated voltage : 400 V Rated Current: 200 – 1200 A Inductance: 0.012 – 0.074 mH Technical specification Type Rated voltage [V] Rated current [A] Uk Linear up to Inductance [μH] R20 [mΩ] Winding weight [kg] NTT MD 953/200 3 x 400 (optional 3×690) 200 8% 300 74 2,1 7 NTT MD 953/400 3 x 400 (optional 3×690) 400 8% 600 37 0,96 11 NTT MD 953/600 3 x 400 (optional 3×690) 600 8% 900 25 0,49 15 NTT MD 953/800 3 x 400 (optional 3×690) 800 8% 1200 18 0,4 19 NTT MD 953/1000 3 x 400 (optional 3×690) 1000 8% 1500 15 0,3 18 NTT MD 953/1200 3 x 400 (optional 3×690) 1200 8% 1800 12 0,18 32

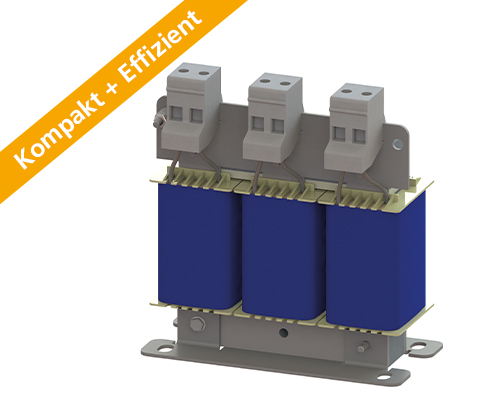

Mains chokes N CNW 905

Three-phase line reactor 2% Uk Description Compact & Efficient The new series not only scores points for its faster delivery time, but also for its resource conservation and increased efficiency. Power Noise Reduction – save up to 15% energy costs. A line reactor relieves the supply network by compensating the harmonics reactive power. The harmonics and commutation notches are reduced strongly. By using a line reactor the inverter electronics and DC-capacitors will be protected. Starting currents and current peaks are reduced up to 30%. Line reactors help to comply with international power quality standards IEEE 519 or EN 61000-3-2. Advantages Compact design Extended service life of electrical consumers Low-temperature rise Attenuation of current spikes up to 30% Reduction of input current up to 15% Low-noise Production possible according to UL insulation system E251513 Typical applications Drive systems for motor drives: Mechanical engineering, Elevators / escalators, Pipes, Conveyor technology, Ventilation and air conditioning, Robotics, Automation technology, Power supplies and Wind turbines Technical Data Rated voltage: U ≤ 3 x 500 V Short circuit: Uk 2% (400VAC/50Hz, INenn) Frequency: 50/60 Hz According to: EN 60289 / EN 61558 Test voltage: LL 2500 V, DC 1min; L-PE 2500 V, DC 1min Insulation class: T40/F Protection rating: IP00 Climatic category: DIN IEC 60068-1 Overload: 1,5 x INenn 1 min / h Design: standing on foot angle Technical specification Type Nominal voltage / nominal frequency UN [V] Nominal current IN [A] Inductance L [mH] Losses P [W Weight [kg Mass Cu [kg] Mass Al [kg] N CNW 903 /3 500 50 / 60 Hz 3 9,800 16 1.0 0.2 – N CNW 903 /6 500 50 / 60 Hz 6 4,880 25 2.0 0.3 – N CNW 903 /8 500 50 / 60 Hz 8 3,680 35 2.0 0.3 – N CNW 903 /10 500 50 / 60 Hz 10 2,930 36 3.0 0.4 – N CNW 903 /12 500 50 / 60 Hz 12 2,450 38 3.0 0.45 – N CNW 903 /16 500 50 / 60 Hz 16 1,830 48 4.0 0.7 – N CNW 903 /25 500 50 / 60 Hz 25 1,170 63 5.2 0.8 – N CNW 903 /36 500 50 / 60 Hz 36 0,810 67 7.0 1.9 – N CNW 903 /50 500 50 / 60 Hz 50 0,590 112 9.0 1.2 – N CNW 903 /70 500 50 / 60 Hz 70 0,420 180 11 2.1 – N CNW 903 /90 500 50 / 60 Hz 90 0,330 144 17 2.5 – N CNW 903 /110 500 50 / 60 Hz 110 0,270 179 18 1.8 – N CNW 903 /125 500 50 / 60 Hz 125 0,235 220 17 2.6 – N CNW 903 /160 500 50 / 60 Hz 160 0,180 145 22 5.0 – N CNW 903 /200 500 50 / 60 Hz 200 0,147 187 26 1.3 3.8 N CNW 903 /250 500 50 / 60 Hz 250 0,118 254 35 1.3 3.0 N CNW 903 /300 500 50 / 60 Hz 300 0,098 250 37 1.3 4.7 N CNW 903 /350 500 50 / 60 Hz 350 0,084 267 45 2.6 5.0 N CNW 903 /400 500 50 / 60 Hz 400 0,074 365 52 2.6 5.2 N CNW 903 /500 500 50 / 60 Hz 500 0,059 423 58 2.9 7.8 N CNW 903 /600 500 50 / 60 Hz 600 0,049 450 71 5.0 6.9 N CNW 903 /700 500 50 / 60 Hz 700 0,042 493 88 5.0 9.2 N CNW 903 /800 500 50 / 60 Hz 800 0,037 545 96 5.1 8.3 N CNW 903 /900 500 50 / 60 Hz 900 0,033 655 108 12.5 10.1 N CNW 903 /1000 500 50 / 60 Hz 1000 0,029 775 108 12.5 10.1 N CNW 903 /1200 500 50 / 60 Hz 1200 0,024 1009 133 13.9 12.4 DIMENSIONS IN MM Type Lenght L1 (mm) Lenght L2 (mm) Broad B1 (mm) Broad B2 (mm) High max. H1 (mm) Mounting N1 (mm) Attachment N2 (mm) Attachment D1 (mm x mm) Terminal/ Cable lug [mm²] Angle [mm x mm] Connection A1 (mm) Connetion D2 (mm) PE N CNW 903 /3 65 78 50 60 95 50 38 5 x 8 2.5 M4 N CNW 903 /6 80 96 55 65 110 56 43 5 x 8 2.5 M4 N CNW 903 /8 125 120 61 66 130 100 45 5 x 8 2.5 M4 N CNW 903 /10 125 120 71 76 130 100 55 5 x 8 2.5 M4 N CNW 905 /12 125 120 71 76 130 100 55 5 x 8 2.5 M4 N CNW 903 /16 155 150 76 76 155 130 54 8 x 12 2.5 M4 N CNW 903 /25 155 150 91 101 170 130 69 8 x 12 10 M4 N CNW 903/36 190 180 81 91 195 170 57 8 x 12 10 M6 N CNW 903 /50 190 180 101 111 195 170 77 8 x 12 10 M6 N CNW 903 /70 230 136 200 176 73 9 x 13 16 (M8) 45 M8 N CNW 903 /90 230 150 200 176 95 9 x 13 16 (M8) 45 M8 N CNW 905 /110 240 150 210 185 97 10 x 18 16 (M8) 45 M8 N CNW 905 /125 240 150 210 185 95 10 x 18 45 M8 N CNW 903 /160 240 175 210 185 103 10 x 18 35 (M10) 55 M8 N CNW 903 /200 300 148 270 224 95 10 x 18 30 x 4 39 11 M12 N CNW 903 /250 300 184 270 224 125 10 x 18 30 x 4 39 11 M12 N CNW 903 /300 300 190 270 224 125 10 x 18 30 x 4 39 11 M12 N CNW 903 /350 340 192 305 248 130 10 x 18 40 x 5 49 13 M12 N CNW 903 /400 360 195 315 264 142 10 x 18 40 x 5 49 13 M12 N CNW