Protection of components

Reliable protection up to IP69K

IP Ingress protection ratings

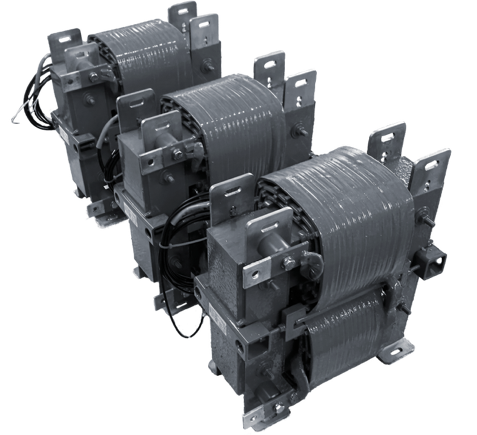

REO products are used in the harshest conditions around the world – at over 40 °C in the desert or at -50 °C in mountainous regions. Water, salt, corrosive media and mechanical effects such as vibrations or oscillations must not have a negative influence. REO components from the heavy-duty sector are specially designed for these environmental influences. Their unique design ensures maximum protection against mechanical, chemical or biological influences and enables high functional reliability and long service life. Thanks to our experience, REO products are known for being reliable even in the most adverse circumstances.

The degrees of protection according to DIN EN 60529

IP (International Protection Code)

1. code number: Protection against solid foreign bodies

No protection

No protection

Large foreign bodies (Ø ≥ 50 mm)

Large foreign bodies (Ø ≥ 50 mm)

Medium-sized foreign bodies (Ø ≥ 12.5 mm, length up to 80 mm)

Medium-sized foreign bodies (Ø ≥ 12.5 mm, length up to 80 mm)

Small foreign bodies (Ø ≥ 2.5 mm)

Small foreign bodies (Ø ≥ 2.5 mm)

Granular foreign bodies (Ø ≥ 1 mm)

Granular foreign bodies (Ø ≥ 1 mm)

Dust deposition

Dust deposition

No dust ingress

No dust ingress

2. code number: Protection against water

No protection

No protection

Protection against vertically falling dripping water

Protection against vertically falling dripping water

Protection against water falling at an angle (up to 15°)

Protection against water spray up to 60° from the vertical

Protection against splashing water on all sides

Protection against splashing water on all sides

Protection against water jets

Protection against water jets

Protection against strong water jets (flooding)

Protection against strong water jets (flooding)

Protection against temporary submersion

Protection against temporary submersion

Schutz gegen dauerndes Untertauchen

Schutz gegen dauerndes Untertauchen

Protection against water during high-pressure / steam jet cleaning (only applies to road vehicles)

Protection against water during high-pressure / steam jet cleaning (only applies to road vehicles)

REO uses high-protection classes to ensure the safety of people and components. We currently offer a protection class value of up to IP69K in a wide range of products. REO components must demonstrate high resilience value under the most challenging test conditions. These include shock and vibration tests, salt spray tests, cold and heat tests, or tests for waterproofing or fire protection.

Paints, protective coatings, potting and complete housings

Especially for electrical components that are used in industrial systems and are subject to strong external influences, reliable protective measures are necessary to ensure trouble-free operation.

REO offers you various options to optimally protect your product – whether with a coating varnish, a special protective coating, encapsulation or a complete housing. REO products thus achieve a high protection class and special resistance to dirt, moisture and other environmental influences.

With REO Mix & Match, you can choose from a wealth of options – combine the different options such as conductor material, winding type and protection to always get the optimal product for your application.

| Paint coating | |

|---|---|

| Contact protection | The required test voltage is met even when immersed in water. |

| Foreign body protection | ★ ★ ★ |

| Moisture protection | ★ ★ ★ |

| Protection class | ★ ★ ★ |

| Fire protection | ★ ★ ★ |

| REO-Protective cover | |

|---|---|

| Contact protection | - |

| Foreign body protection | ★ ★ ★ |

| Moisture protection | ★ ★ ★ |

| Protection class | ★ ★ ★ |

| Fire protection | ★ ★ ★ |

| Housing | |

|---|---|

| Contact protection | ★ ★ ★ |

| Foreign body protection | ★ ★ ★ |

| Moisture protection | ★ ★ ★ |

| Protection class | ★ ★ ★ |

| Fire protection | ★ ★ ★ |

| REO Xtreme | Extreme wetness protection | |

|---|---|

| Contact protection | The required test voltage is met even when immersed in water. |

| Foreign body protection | ★ ★ ★ |

| Moisture protection | ★ ★ ★ |

| Protection class | ★ ★ ★ |

| Fire protection | ★ ★ ★ |

PROTECTIVE COATING

The MPS protective coating (Moisture Protection System) is an essential part of the REO insulation system and one of the most unique selling points of our components The MPS protective coating developed by us is available exclusively from REO. It provides your components with reliable, long-term protection against a wide range of environmental influences: To provide the necessary protection outdoors against abrasion from the pantograph, brake dust, metal abrasion, snow and ice, our components receive this special protective coating in addition to VPI impregnation.

This allows the components to be enclosed (IP20) and exposed to unfiltered cooling air. A major advantage, for example in the field of railway technology, with regard to the flexibility of railway constructions. REO relies on this MPS protective coating from pollution degree PD3A.

REO only applies the coatings and varnishes in strict compliance with the necessary safety measures. Elaborate filter systems and safety standards ensure minimal impact on people and nature.

Advantages:

- Superior moisture protection

- High resistance to stone impacts

- High abrasion resistance (desert sand resistant)

- Suitable for pollution degree > PD3A

- High tracking resistance (CTI > 600V)

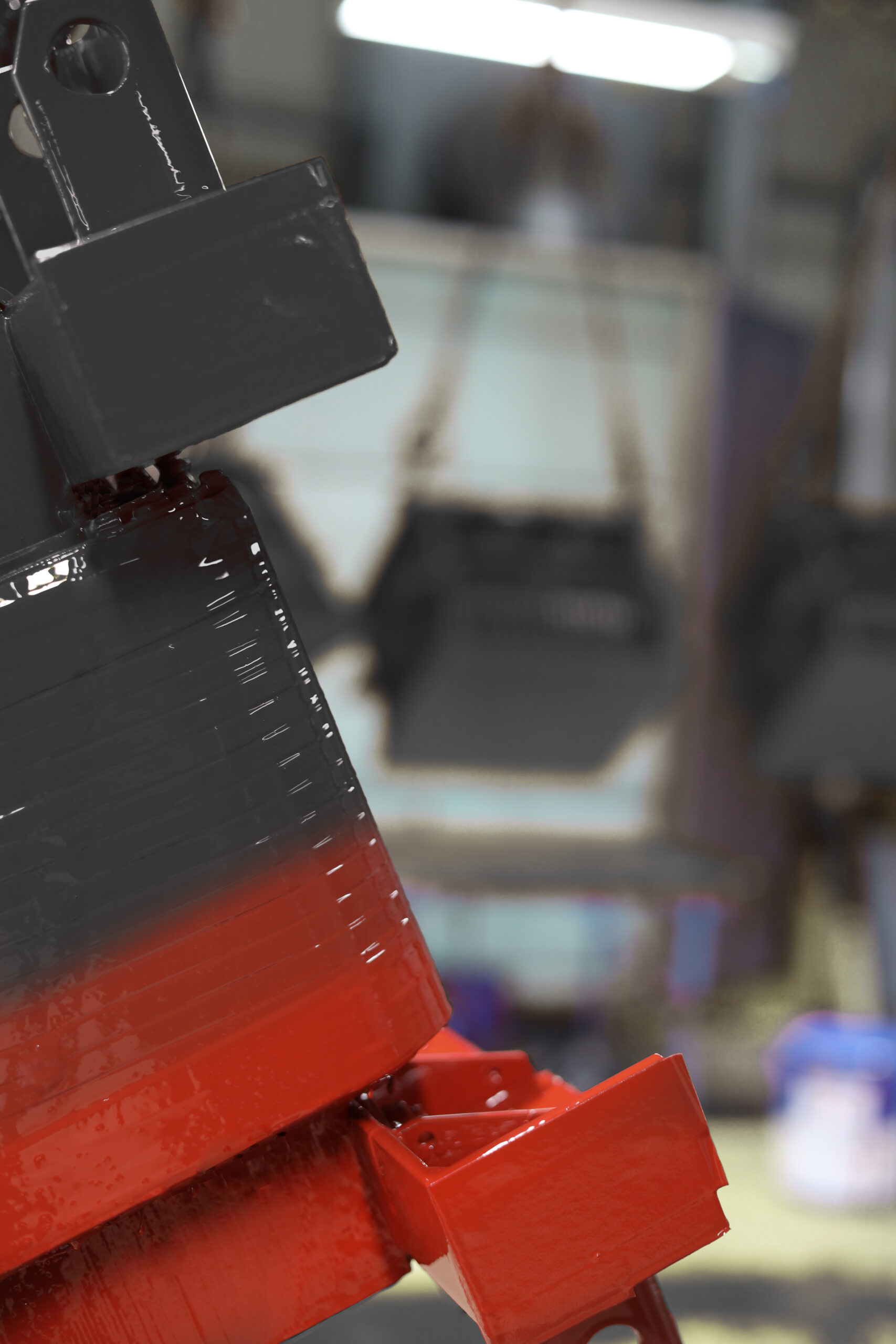

By changing the color of our coating from red to grey, we are starting to use a new, environmentally friendly material – without compromising on quality, of course. The new material offers the same high resistance to weathering, UV radiation and mechanical influences as before, but is significantly more sustainable in terms of production and disposal. In this way, we are making an important contribution to environmental protection while offering you the usual durability and reliability of our products.

Permanently flexible

Remains elastic after curing and ensures long-term flexibility

Excellent heat resistance

Resistant to temperatures up to 180°C 356°F – ideal for applications with high heat loads

Reliable consistency

High weather and moisture resistance for use outdoors or in extreme environments

More environmentally friendly

Casting technology

Electrical components that are used in industrial systems and are subject to strong external influences in particular require reliable protective measures to ensure trouble-free operation. To achieve this, potting technology involves treating the electrical components with potting compound in a vacuum pressure process and providing them with partial or full potting. The potting provides reliable protection against external influences such as water, brake dust and deposits and also ensures a longer service life for the components.

The REO experts will be happy to answer your questions at any time.